Machine Turning at CED

Machine Turning simple to complex parts with extreme tolerance accuracy is a mainstay advantage at CED Services. Our spectrum of advanced CNC Turning centers can process small to very large stock that includes Alloy Steels, Stainless Steel, Titanium, Copper, Aluminum, Acrylic, Delrin, PVC, Nylon, and more.

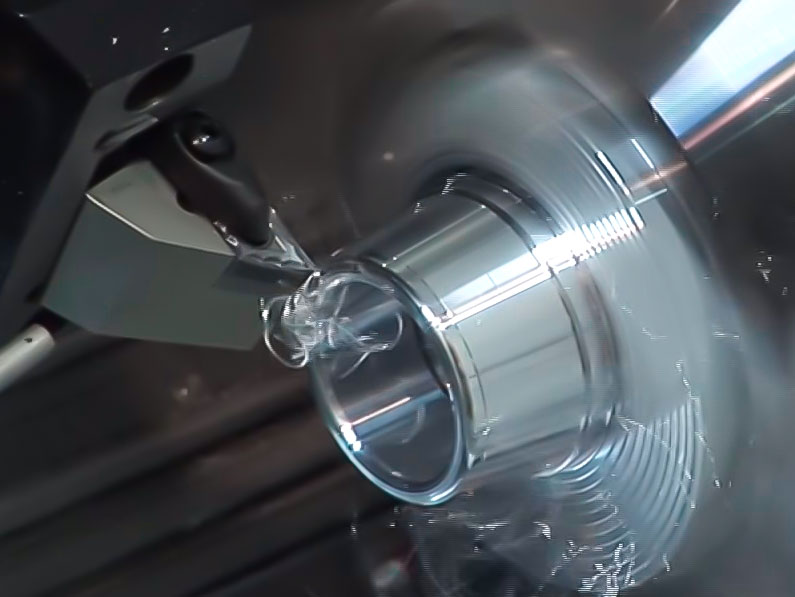

Turning is a machining process used to make cylindrical parts, where the cutting tool moves in a linear fashion while the workpiece rotates. Our AS9100D/ISO9001:2015 Certificate confirms that the complex parts we machine meet the strict standards established for the turning of Medical components, Aerospace parts, Industrial equipment, and more. We maintain a stable turning environment where temperature, humidity and cleanliness are carefully monitored and maintained.

Machine-Turned parts with monitored Quality Assurance

Our top-of-the-line Turning Machinery is complimented by a dedicated Quality Assurance Lab where continual testing, measuring, and assessment ensure part and component excellence throughout the part turning cycle.

Looking for a better resource for simple to complex Turned Parts? Look to CED, the Connecticut (CT) company that achieves world-class quality by combining a mastery of advanced turning technologies with New England ingenuity and work ethics.

CED’s Machine Turning equipment includes:

- 1 Mazak CNC Quick Turn

25 HP 2.8 dia thru spindle - 1 Mazak CNC Super Quick Turn

18HP, 2 ½” thru spindle - 1 Mazak CNC Quick Turn

20HP, 2″ thru spindle - 1 Mazak CNC Quick Turn

10HP, 1 ½” thru spindle - 1 Takisawa Lathe

15” - 1 Hardinge W/DRO

with .0001 Res.

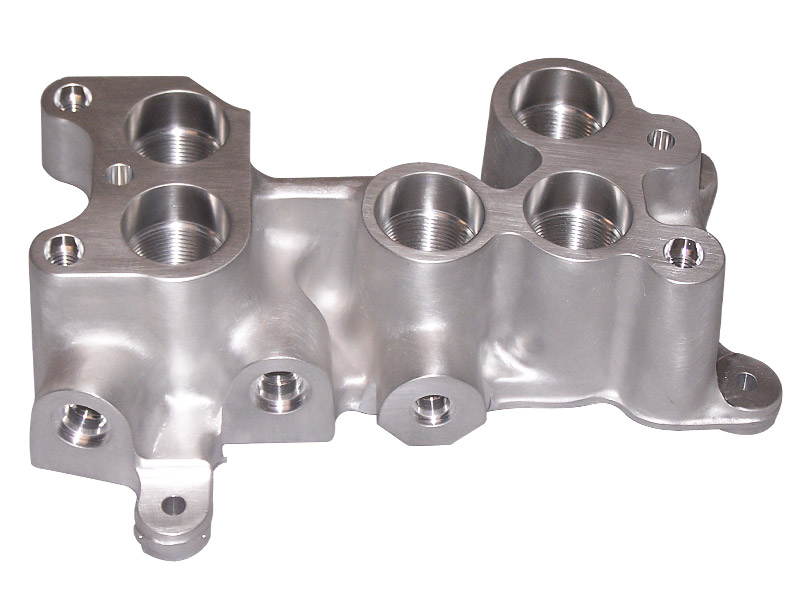

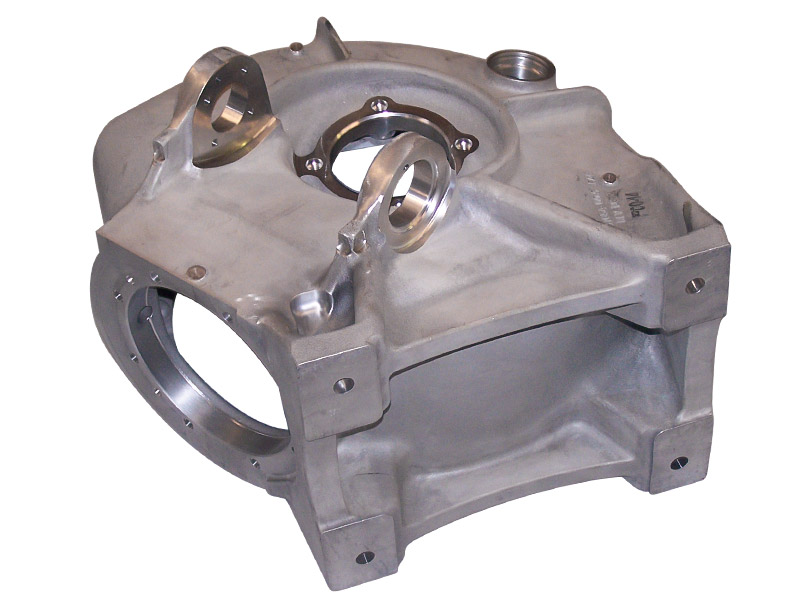

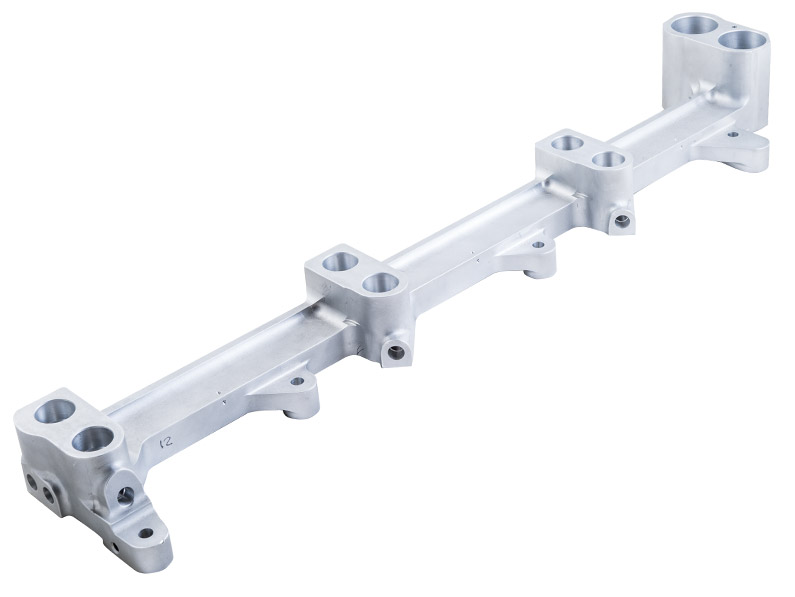

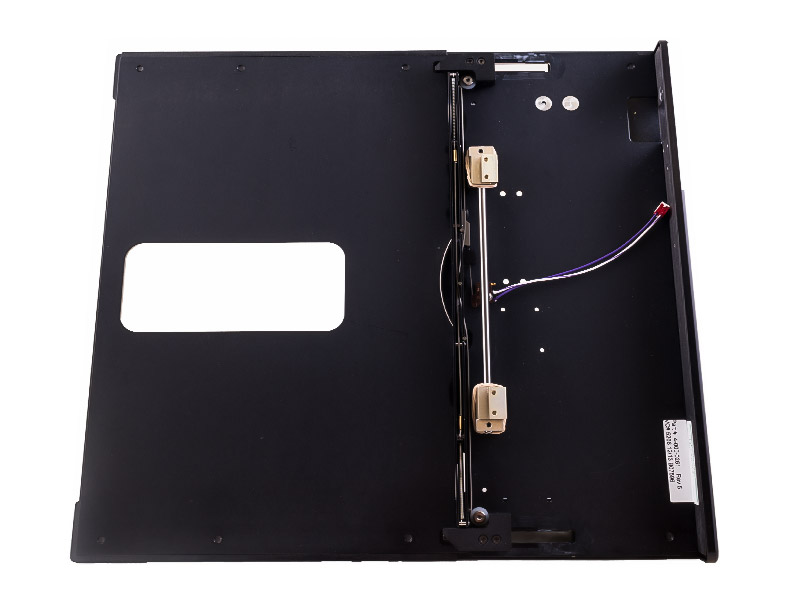

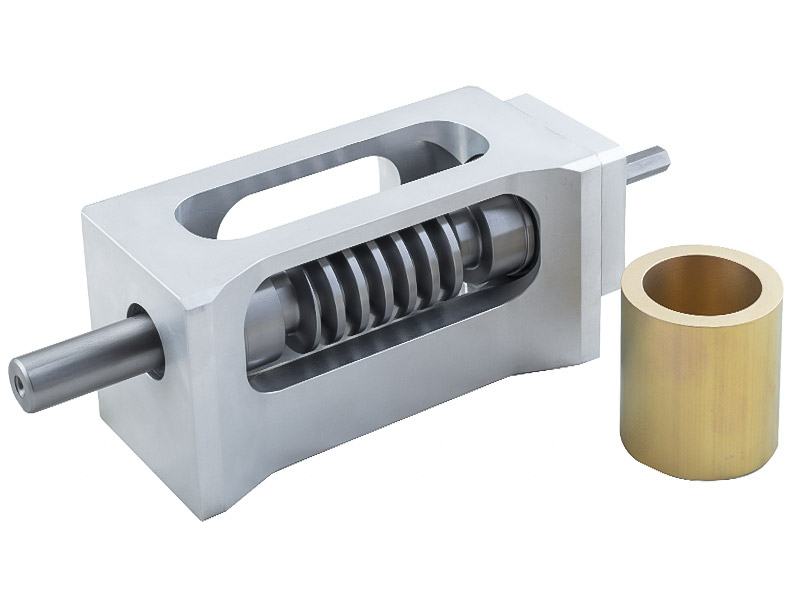

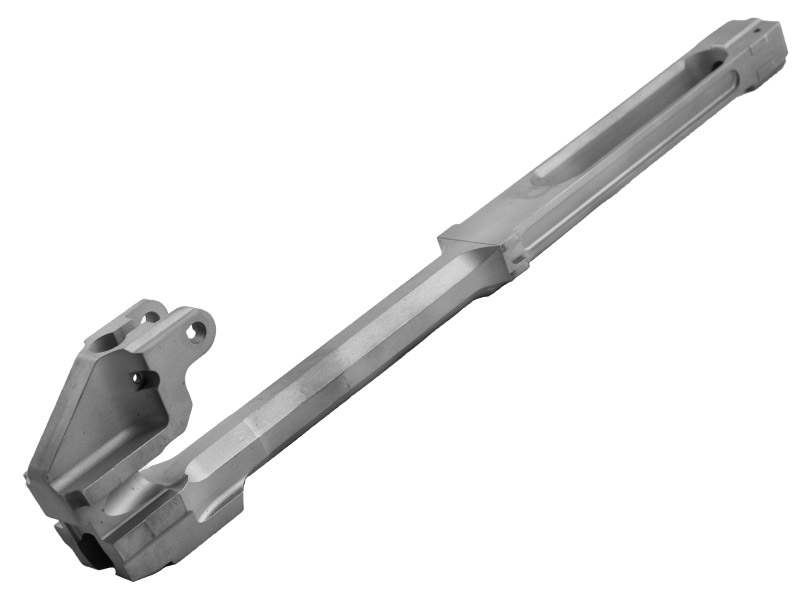

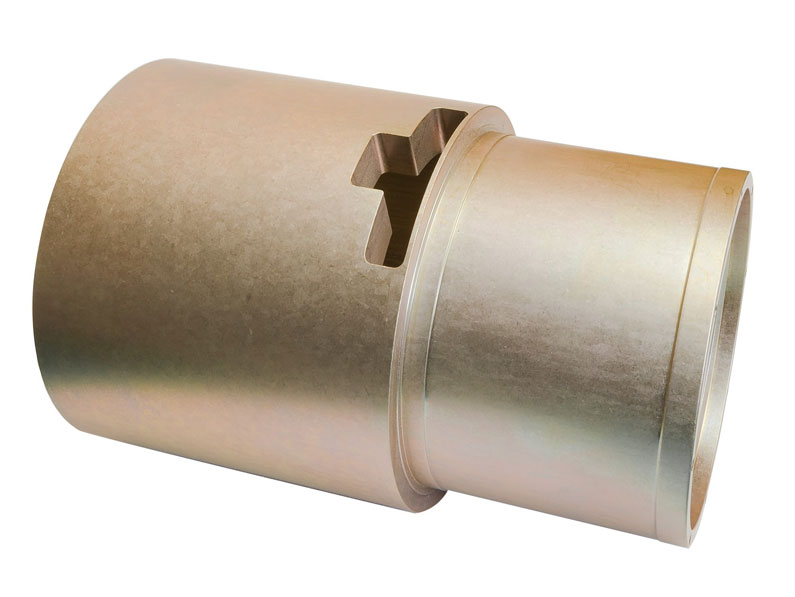

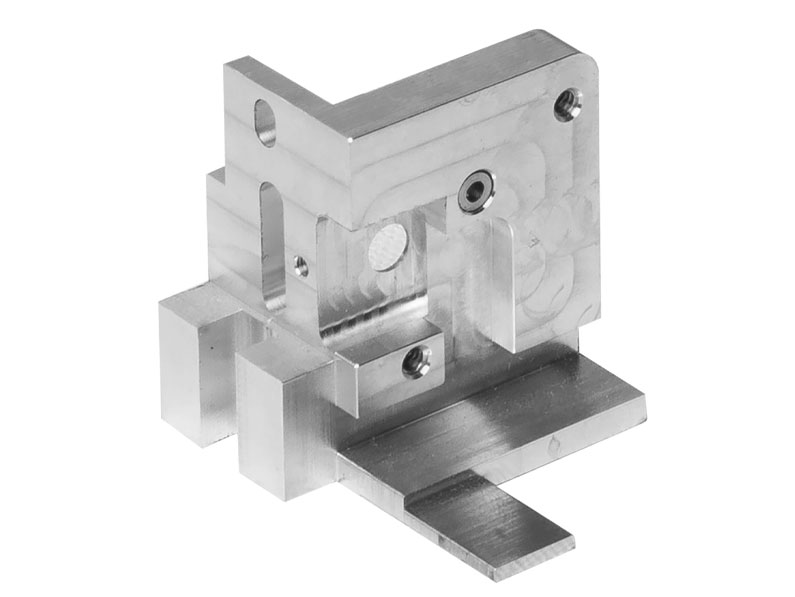

CED Machined Parts and Components Gallery

(click images to enlarge)

Contact CED Services

Have a question? Need a quote?

Call or email us today!

203-828-6528

6 Reasons to consider CED :

1. Diverse Capabilities: Our advanced equipment and AS9100D/ISO9001:2015 Certificate ensure specified-precion for parts and subassemblies used in the most demanding industries.

2. Customer Dedication: Experienced professionals focused on your part program success.

3. Lower Cost: Consistently higher-quality parts—machined for less.

4. Convenient Location: Nestled in Oxford, Connecticut, USA — only 1 mile from Oxford Airport.

5. Vendor Upgrade Program: Our 3-step program eliminates vendor-switching nightmares.

6. Reputation: Our world-class precision and service have earned praise and trust from our customers...

Read what CED clients say:

“We enjoy our relationship with CED for several reasons namely, that they have the expertise that our products require and the equipment that can efficiently produce it. Their decision making people are skilled in their areas of expertise. This, plus their attitude of "what can we do to help you" is a combination that has served us well.”

Tom Chiaramonte, Engineer | Triumph Actuation Systems

“CED has consistently proven they can produce top quality fabrications. The staff at CED offers outstanding Engineering support. The cycle time associated with design, prototyping and assembly verification is greatly reduced due to CED's commitment to quality and service.”

Tom Farbizio , Engineer | Hologic Inc.

Consulting, Engineering & Development Services, Inc.

3 Fox Hollow Road,

Oxford, CT 06478